PATHWAY TO

SUCCESS

Success Fabrication has grown at an incredible rate since 2005 and constantly find ourselves upscaling to produce the very best products we can. In January 2012, we moved into our purpose-built 1200sq.m factory, featuring a 15m ceiling supported by two 10-tonne cranes, and front doors that open an astonishing 17 meters wide.

On top of that, we have a 650sqm concrete area next to the factory where future gantry cranes will aid in storage and assembly, with another 3,000 sqm storage/laydown or trial assembly area. When it comes to steel fabrication, we’re committed to maintaining our high standards and ensuring we complete projects efficiently.

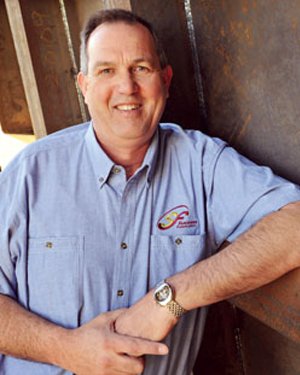

GRAEME'S

THE MAN TO SEE

With more than 30 years of active steel fabrication experience, Graeme Phillips leads the team at Success Fabrication and knows the industry better than anyone. Though he now concentrates on generating new business and managing workflow and quality control, he still gets his hands dirty on the factory floor from time to time.

THE TEAM

Our team is a small, close-knit group of qualified boilermakers, flux core coded welders and apprentices, all overseen by Graeme. Every member is a professional and has the skills to fill their role, no matter the task.

All of us here subscribe to the adage that “teamwork breeds success”, so we take that enthusiasm and motivation and put it behind all of our steel fabrication.

KEEPING GOOD COMPANY

If you can be judged by the company you keep, Success Fabrication is proud and very fortunate to be able to say that we’ve had some of the biggest names in the industry turn to us for steel fabrication on the following projects:

- BHP Billiton

- Civmec

- CSI

- Goodline

- Monadelphous

- Rio Tinto

- Roy Hill

- Sino Iron

- Fortescue Metals

- Utha Point